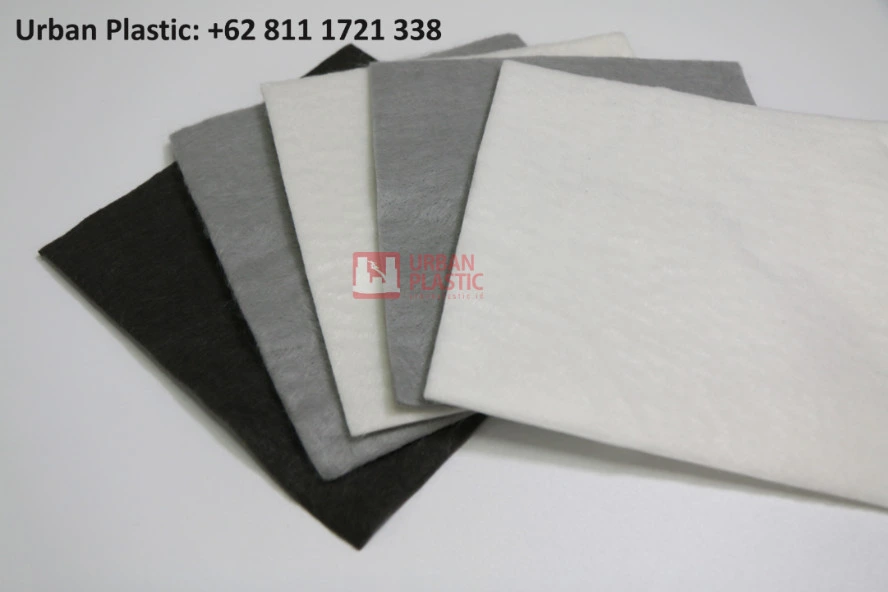

When it comes to talking about the production of geotextile fabric suppliers Sydney, there are some different ways. This material has some advantages such as high durability and strength.

This supports its use in construction projects with various levels of complexity. Geotextile is a synthetic material and this kind of building material can be used in many ways. This is possible since it has positive qualities and is versatile.

Geotextile Fabric Suppliers Sydney, The Production

This material is mostly produced using conventional or classic production techniques. There are three main classifications for its manufacturing processes which are classic, specialized, and composite.

In classic geotextiles, the products such as knitted, woven, and non-woven fabrics which are industry products are considered. Meanwhile, special geotextile even though it has the appearance of classic geotextile such as mesh, matte, and webbing, are not direct products of textile technology.

1. Classic production

This type is created in two steps including manufacturing fibers, filaments, tape, or yarn. These elements then turned into fabric. There are some techniques used to make the components needed which will be discussed below.

Filaments for geotextile fabric suppliers Sydney are created through extrusion techniques. These include wetting, drying, and melting. Molten extrusion is used for polypropylene and polyester which are types of polymers.

They are used to create fiber and synthetic-based geotextiles. Here, the spinnerets or dies are used to extrude molten polymers. They are subsequently stretched along the filament axis in such a way.

This results in the improvement in molecular orientation along the filament and make high tensile properties. When the spinnerets pulled out numerous filaments simultaneously, it is known as multifilament yarn.

They are cut into 2 to 10 cm and this is known as the staple fibers. After that, they are twisted together and the final result is yarn. The next component used by geotextile fabric suppliers Sydney is slit film.

This component is made using slit dice and through a molten extrusion. The slice dice are cut with a sharp blade. These films can then be fibrillated and divided as well into fibrous strands. This is known as fibrillated yarn.

The slit film, fiber, yarn, or filament which are the constituent materials are transformed into various classic and specialty geotextiles.

2. Special production

The first thing to be discussed in the special production is webbings. It is created from strips of medium width. It is similar to thick woven slit film fabric.

Next is nets. It contains two sets of extruded strands lined up in a biased direction. Usually, this component used by geotextile fabric suppliers Sydney is partially fused to one or both strands.

The molten extrusion process can also be used to produce these net structures. The process consists of a dye spun with slits at the edges in which the liquid polymer is extracted.

3. Composite production

This last thing is created from the combination of several products mentioned above. For instance, by combining multiple layers of non-woven, woven, and knitted material. It can be made by needle punching, thermal bonding, and stitching.

Finding quality geotextile products nowadays is easy. You can buy it from reliable geotextile fabric suppliers Sydney or BaliGEOTEX from Indonesia and get the best offer from them.

For more information about Geotextile Fabric please contact: Whatsapp/Mobile Phone : +62 811 9151 338 (Ms. Anna), or Email : info@urbanplastic.id.