What is needle punched geotextile? You may ever heard about this process, especially when we are talking about making the non-woven geotextile.

Geotextile is a durable material and can reduce the possibility of landslides or soil damage. If classified, geotextiles are included in the geo-synthetic group which can provide benefits in geotechnical engineering structures.

Besides that, it is also good for the environment to maintain soil stability and strength. That is why; you may see this product is used in many land or road projects.

What is Needle Punched Geotextile?

Needle Punching is a textile made from polymer materials, which pass water, in the form of weaves, knitted or non-woven (non-woven). Those are used in geotechnical and civil engineering.

Geotextile Nir-Woven (Non-Woven) is a geotextile that is not weaving. The process of joining fibers together its formation occurs due to mechanical processes with small needle punctures or put together with heat.

This type of geotextile is made from polypropylene staple fibers. The applications of this material are in many building applications and civil engineering, and these are designed to offer several functions.

Those functions are separation, filtration, and also erosion control. These products are exceptional for drainage, railway, road, and landfill.

The needle punching process has been widely used for water filters, automotive, and other applications. Almost all well-known car brands have used these kinds of products.

The advantage of using this method is strong dampening power to perfectly reduce engine vibrations, making driving comfortable. That is an example from the automotive industry right now.

Other Details to Know

What is needle punched geotextile? The information above tells us about the definition. However, you still need to find any other details, and below are the essential notes to know.

1. Act as a Separator

In its use, this non-woven or needle-punched geotextile is used as a separator. The aim is to prevent any intermixing chances of the different soil that has different layer types.

Besides that, this geotextile also acts as a filter. This filter will allow the fluids’ flow but still prevent the soil particles from passing well.

2. Resistant to some chemicals

This type is durable and has a long lifespan because it is resistant to the commonly encountered ground chemicals. It is also resistant to other things such as mildew and insects.

You should know that this needle-punched geotextile is non-biodegradable. Furthermore, it is highly resistant to alkaline and acid environments. It means that you have to consider placing it in the right area.

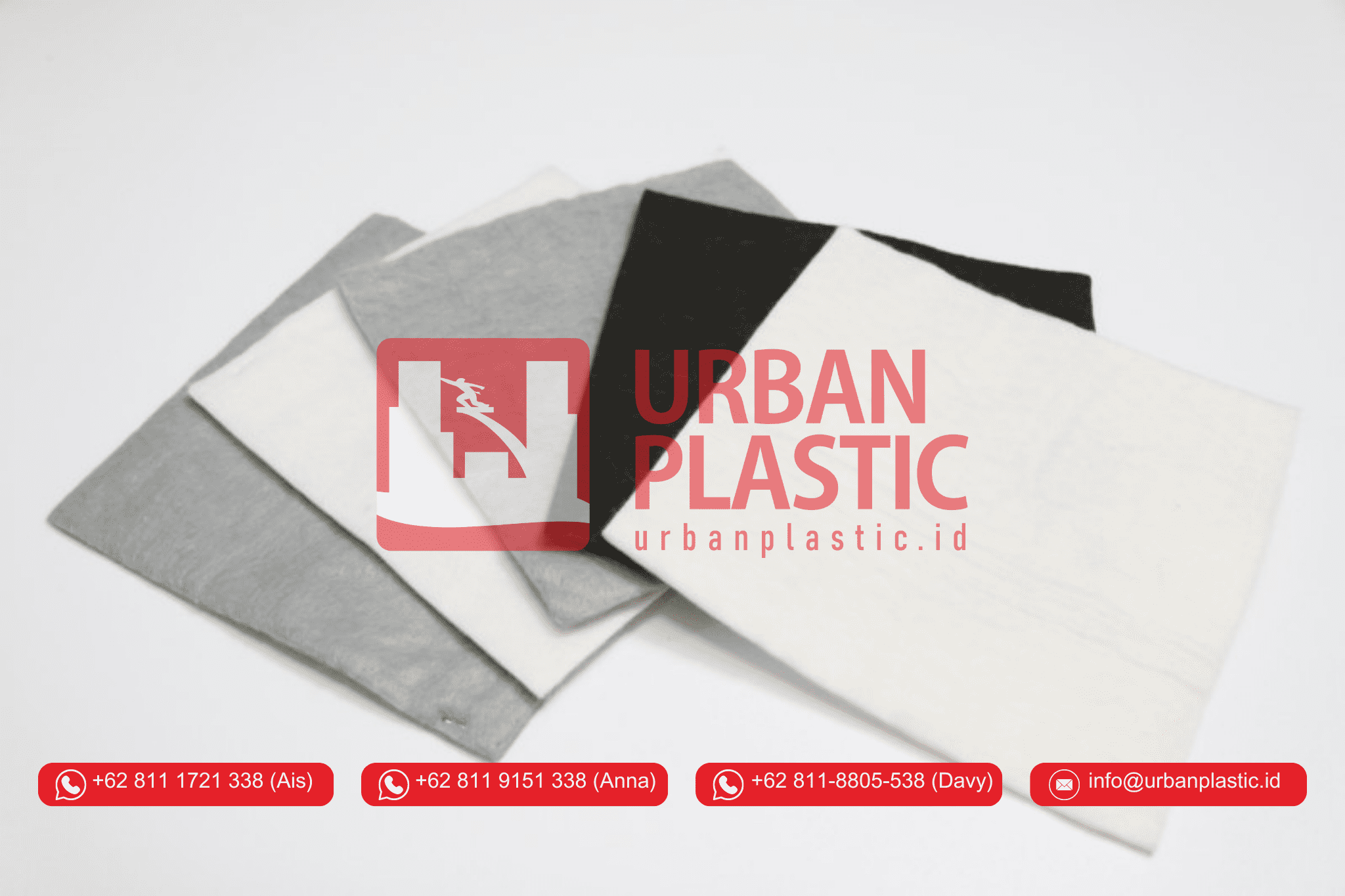

3. Various Thickness Types are Available

The Manufacturers produce this geotextile in several thickness variants. You can choose based on your needs, and please remember that the thicker material is usually stronger.

Some available thickness levels are 140 gsm, 100 gsm, and more. Usually, the manufacturer will give the complete details on their website. You can see everything there or call customer service if you have any questions.

So, once again, what is needle punched geotextile? This production method uses a large number of needles that have a barbs shape. It will move vertically so that the fibers interspersed up and down as well.

For more information about geotextile non woven please contact: Whatsapp/Mobile Phone: +62 811 1721 338 (Ms. Ais) or Email : info@urbanplastic.id.