Geotextile fabrics have revolutionized modern construction and civil engineering practices. These synthetic fabrics, used for their superior soil stabilization properties, are critical in enhancing the durability and efficiency of various infrastructural projects. Their versatility and effectiveness in applications ranging from road construction to erosion control make them indispensable in the industry.

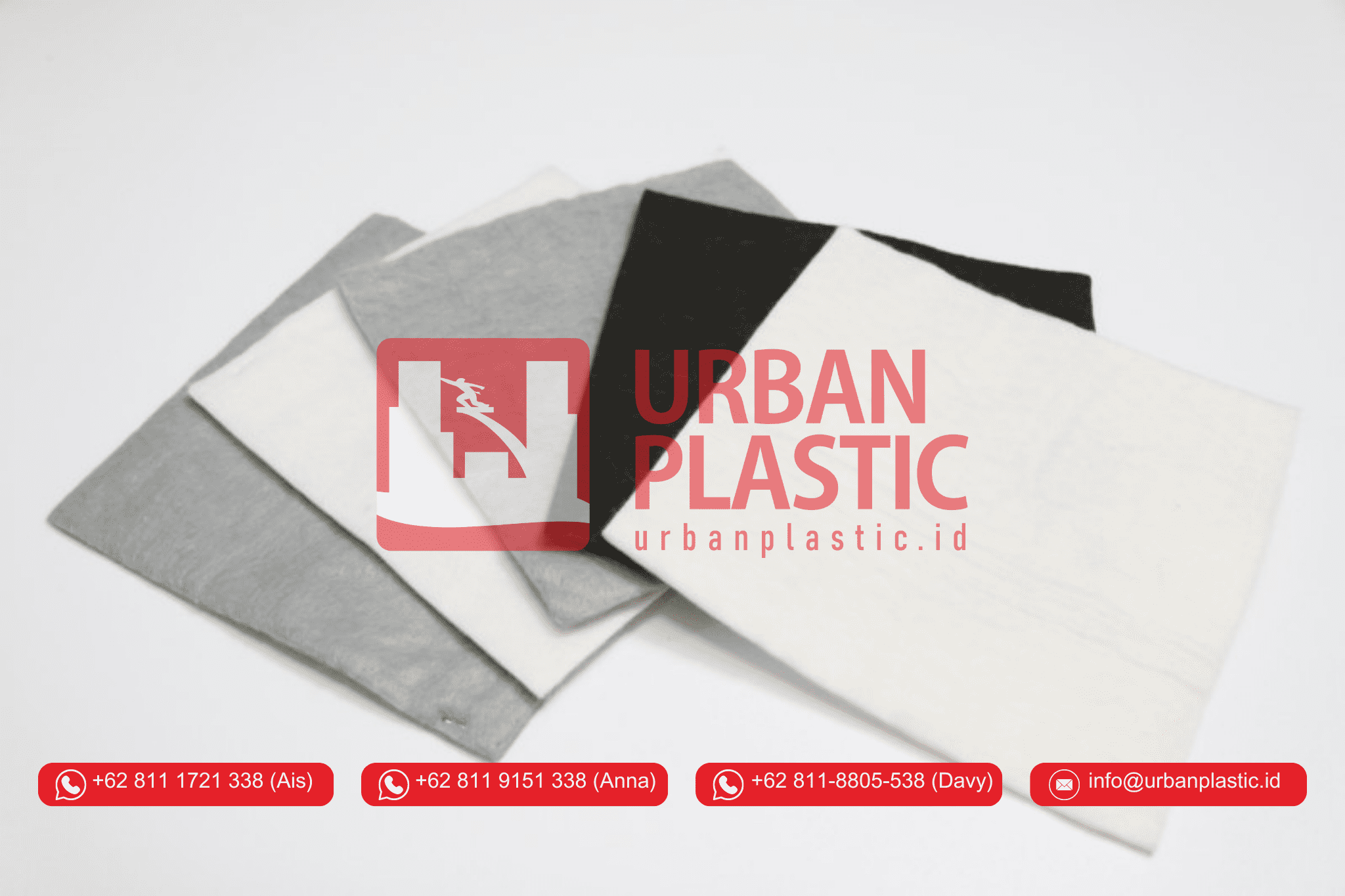

Geotextile Fabrics

Definition and Basic Properties

Geotextile fabrics are permeable textiles made from synthetic polymers such as polypropylene and polyester. These materials are designed to enhance the mechanical and hydraulic properties of soil, providing stability and support in construction projects.

Comparison with Similar Products

Geotextile fabrics differ from other geosynthetics like geomembranes and geonets. While geomembranes are impermeable and used as barriers, geonets are primarily used for drainage. Geotextiles, however, combine filtration, drainage, separation, and reinforcement functions, making them highly versatile.

Manufacturing Processes

There are three primary types of geotextile fabrics based on their manufacturing processes:

- Woven Geotextiles: Produced by weaving fibers together, these fabrics exhibit high tensile strength, making them ideal for reinforcement applications.

- Nonwoven Geotextiles: Made by bonding fibers through chemical, thermal, or mechanical means, these fabrics offer excellent filtration and drainage properties due to their porous structure.

- Knitted Geotextiles: These are created using knitting techniques, providing a balance of flexibility and strength suitable for specific applications like slope stabilization.

- Key Functions and Benefits

- Soil Stabilization

- Geotextiles improve soil strength and prevent erosion, making them crucial in constructing embankments, roads, and foundations. They enhance the load-bearing capacity of the soil, distributing loads evenly and reducing settlement risks.

Filtration and Drainage

Geotextile fabrics allow water to pass through while retaining soil particles. This filtration capability prevents clogging and maintains the soil’s permeability, ensuring efficient drainage and reducing water accumulation that could weaken structures.

Reinforcement

Geotextiles act as reinforcement layers, providing additional support to weak soils. This increases the overall stability and load-bearing capacity, essential for constructing durable roads and embankments.

Separation

In road construction, geotextiles prevent the mixing of different soil layers, such as subgrade and aggregate, maintaining the integrity and strength of the road structure.

Types and Selection

Woven Geotextiles

These are characterized by their high tensile strength and low elongation. They are ideal for applications requiring strong reinforcement but have lower permeability compared to nonwoven types.

Nonwoven Geotextiles

Nonwoven geotextiles are known for their excellent filtration properties and ability to conform to soil surfaces. They are preferred in drainage and filtration applications where high permeability is required.

Knitted Geotextiles

Combining the properties of woven and nonwoven geotextiles, knitted geotextiles offer good flexibility and moderate strength. They are used in applications that require both reinforcement and adaptability to complex surfaces.

Selection Criteria

- Soil Type: The choice of geotextile depends on the soil characteristics. Nonwoven geotextiles are suitable for fine-grained soils, while woven geotextiles are better for coarse-grained soils.

- Environmental Conditions: Wet environments require geotextiles with high drainage capacity, while dry conditions might benefit more from durable woven types.

- Application Specifics: For heavy-duty projects like road construction, woven geotextiles are preferred. For landscaping or erosion control, nonwoven geotextiles are ideal.

- Applications in Various Industries

- Road Construction

- Geotextiles are extensively used in road construction to reinforce the soil, improve load distribution, and prevent road damage due to erosion and settlement.

Railways

In railway construction, geotextiles are used to separate soil layers, enhance drainage, and provide stability to the tracks, ensuring safety and durability.

Embankments

Geotextiles provide support and prevent erosion in embankment construction. They control water flow and reduce the risk of structural failure during heavy rains.

Drainage Systems

In drainage systems, geotextiles filter soil particles while allowing water to pass through, maintaining efficient water flow and preventing blockages.

Coastal Work

Geotextiles stabilize shorelines, prevent erosion, and support vegetation growth, protecting coastal areas from the impact of waves and storms.

Conclusion

Geotextile fabrics are a vital component in modern construction and civil engineering, offering solutions that enhance the durability and efficiency of projects. Understanding their types, functions, and best practices ensures optimal use of these versatile materials. By integrating geotextiles into your construction projects, you can achieve more stable, durable, and cost-effective results.

For more information about Geotextile please contact: Whatsapp/Mobile Phone: +62 811 1721 338 or Email : info@urbanplastic.id.