Selecting the appropriate geotextile filter fabric is crucial for the success and longevity of your construction projects. Geotextile filter fabrics are essential in various applications such as soil stabilization, erosion control, and drainage systems. This article will guide you through understanding these materials, their key functions, types, selection criteria, and best practices for installation, backed by case studies demonstrating their effectiveness.

Understanding Geotextile Filter Fabric

Definition and Basic Properties

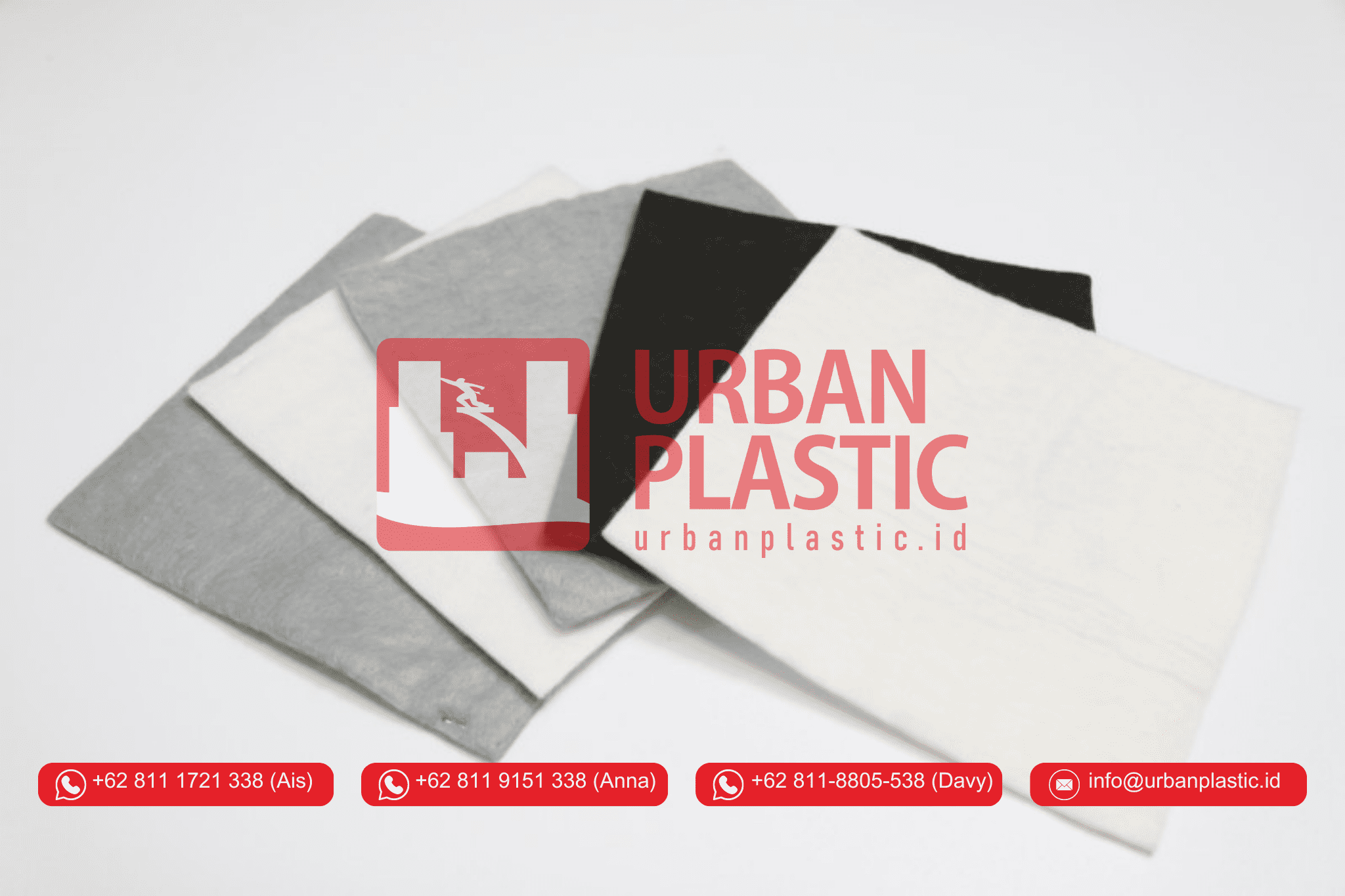

Geotextile filter fabrics are permeable textile materials used in conjunction with soil, rock, or any other geotechnical engineering-related material. They are primarily made from polymers like polypropylene or polyester, offering durability and resistance to environmental factors. These fabrics are designed to allow water to pass while retaining soil particles, making them ideal for filtration and separation tasks.

Comparison with Similar Products

Geotextile filter fabrics are often compared with other geosynthetics such as geomembranes and geogrids. Unlike geomembranes, which act as barriers, geotextile fabrics facilitate filtration and drainage. Geogrids, on the other hand, are used primarily for reinforcement purposes. Geotextile filter fabrics combine the benefits of filtration and reinforcement, making them versatile for various applications.

Manufacturing Processes

Geotextile fabrics are manufactured through three primary processes:

- Woven Geotextiles: Produced by weaving fibers together, offering high tensile strength and stability.

- Nonwoven Geotextiles: Made by bonding fibers together using heat, chemicals, or needle punching, providing excellent filtration properties.

- Knitted Geotextiles: Created through knitting techniques, offering flexibility and moderate strength.

Key Functions and Benefits

Soil Stabilization

Geotextile filter fabrics enhance soil stability by improving load distribution and reducing settlement. They help maintain the integrity of soil structures, making them essential for roadways, embankments, and foundations.

Erosion Control

These fabrics protect soil from erosion by water and wind. They are used in retaining walls, slopes, and riverbanks to prevent soil loss and maintain landscape integrity.

Drainage and Filtration

Geotextile fabrics allow water to pass through while filtering out soil particles, preventing clogging and maintaining efficient drainage systems. This function is critical in road construction, retaining walls, and agricultural applications.

Reinforcement

Geotextiles provide reinforcement by increasing the load-bearing capacity of weak soils. They act as a stabilizing layer, enhancing the structural integrity of pavements, embankments, and other load-bearing structures.

Types and Selection

Woven Geotextiles

Woven geotextiles are characterized by their high tensile strength and low elongation. They are ideal for applications requiring strong reinforcement, such as road construction and embankments. However, their filtration capabilities are limited compared to nonwoven geotextiles.

Nonwoven Geotextiles

Nonwoven geotextiles offer superior filtration and drainage properties due to their porous nature. They are suitable for drainage systems, soil separation, and erosion control. Their flexibility allows them to conform to various soil profiles, making them versatile for different applications.

Knitted Geotextiles

Knitted geotextiles provide a balance between strength and flexibility. They are used in applications where moderate reinforcement and adaptability are required, such as in coastal protection and landfill covers.

Selection Criteria

When selecting geotextile filter fabrics, consider the following factors:

- Soil Type: Different soil conditions require different types of geotextiles. For sandy soils, woven geotextiles are preferable, while nonwoven geotextiles are better for clayey soils.

- Environmental Conditions: Consider the project’s exposure to elements like water, temperature, and chemicals. Nonwoven geotextiles are better suited for wet conditions due to their drainage capabilities.

- Application Requirements: Match the geotextile’s properties with the specific needs of your project, such as filtration, reinforcement, or erosion control.

Applications in Various Industries

Road Construction

In road construction, geotextile filter fabrics are used to separate soil layers, reinforce the base, and enhance drainage. This prevents road degradation and extends the lifespan of the roadway.

Railways

Geotextiles in railway construction help stabilize the track bed, improve drainage, and prevent soil contamination. They ensure the stability and longevity of the railway infrastructure.

Embankments

Geotextile fabrics reinforce embankments, prevent erosion, and control water flow. They are essential for the stability and durability of these structures, especially in flood-prone areas.

Drainage Systems

Geotextiles maintain efficient drainage by filtering soil particles while allowing water to pass through. They are used in underground drainage systems, retaining walls, and agricultural drainage to prevent waterlogging and soil erosion.

Coastal Work

In coastal engineering, geotextile filter fabrics protect shorelines from erosion, stabilize sand dunes, and support vegetation growth. They play a vital role in preserving coastal areas against wave action and storms.

Agriculture

Geotextiles improve soil structure, prevent erosion, and enhance drainage in agricultural fields. They are used in various applications such as irrigation systems, greenhouse flooring, and soil stabilization.

Installation Best Practices

Site Preparation

Proper site preparation is crucial for effective geotextile installation. Clear the area of debris and vegetation, and ensure the ground is smooth and compacted. This prevents damage to the geotextile during installation.

Laying Techniques

Lay the geotextile fabric flat, with overlaps of at least 30 cm to ensure full coverage. Secure the edges with pins or staples to prevent movement. For slopes, anchor the fabric at the top and bottom to maintain stability.

Anchoring Methods

Use anchor trenches or weights to secure the geotextile in place. This is especially important in windy conditions or when working on slopes. Proper anchoring ensures the fabric remains in position and functions effectively.

Follow Manufacturer Guidelines

Always adhere to manufacturer guidelines and industry standards for installation. This ensures optimal performance and longevity of the geotextile filter fabric.

Avoid Common Mistakes

Common installation mistakes include insufficient overlap, improper anchoring, and inadequate site preparation. Avoid these errors to ensure the geotextile performs as intended and provides the desired benefits.

Choosing the right geotextile filter fabric is essential for the success of your construction projects. Understanding the properties, functions, and types of geotextiles will help you make informed decisions. By following best practices for installation and considering case studies, you can ensure the effective and long-lasting performance of geotextile filter fabrics in various applications.

For more information about Geotextile please contact: Whatsapp/Mobile Phone: +62 811 9151 338 or Email :info@urbanplastic.id