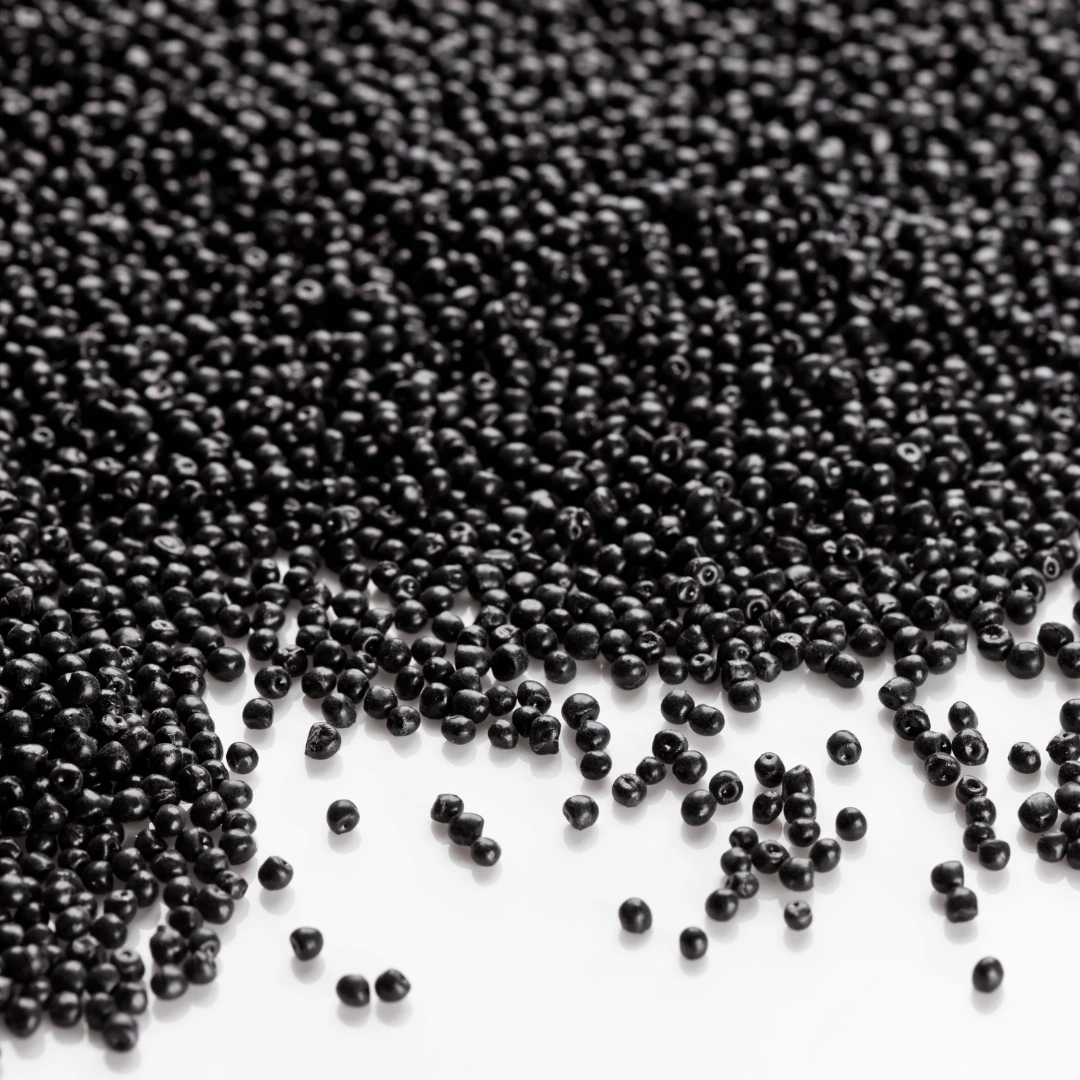

Resin Plastic

Product Details :

PT. Urban Plastic Indonesia with the Urban Plastic brand sells all kinds of plastic seeds for the needs of our customers. We sell PP, HDPE, LDPE, PE plastic seeds and also sell Recycled plastic seeds.

Please contact us to consult about plastic seeds that suit your needs right now.

The best plastic pellet producer Urban Plastic is one of the plastic manufacturers which is currently proven to provide the best quality in each of its products. The need for the use of plastic-based products is currently increasing, such as the use of plastic bags. This makes plastic producers produce plastic garbage bags every day. Therefore, we can easily find so many sellers of plastic bags both at grocery stores, traditional markets, supermarkets, to well-known supermarkets. The sizes offered from plastic bags also certainly vary according to consumer needs. Ranging from small plastic bags to the largest or jumbo available. In addition, various colors of plastic bags have various variations.

The process of making plastic pellets – Urban Plastics as plastic bags

Previously, many of us were unfamiliar with the process of making plastic bags, from the best plastic seed producer – Urban Plastic. So that plastic can be like what you use today, namely plastic bags. The process of making this simple product turns out to take quite a long time. This is because there are several types of plastic that have different resistance, so the process of making plastic also uses different methods. The first step in making plastic bags must be done in a plastic making machine, namely the injection molding process. At this stage the plastic is still in the form of plastic seeds or commonly called pellets. This material will later be put into a taung that has a heater.

This heating process will melt the pellets to combine every material in the tube. After that, the plastic seed material will go through an extrusion process. This extrusion process is a process in which the plastic seed will enter the mold, then press continuously until it melts. In this process, a safe temperature is needed so that this printing process can form products from the best selling plastic seeds – Urban Plastic has maximum quality. After this process is complete, to make it into plastic plates using a process known as thermoforming. This plastic sheet or sheet is then reheated and put into another mold. This stage takes less time than the previous process.

Then the final process of making plastic bags from the best plastic seed producer – Urban Plastic, is the blow molding process. This process will make the melted plastic ore which has formed another shape, namely this pipe will be blown continuously into the mold. Then a plastic is formed which is ready to be formed and then the next process is carried out into an object that is used for everyday life. Some of the products made from these plastic seeds include food wrappers, drink bottles, household appliances, and many more. Keep in mind when you use plastic bags as a container for shopping for vegetables, food, and drinks, you shouldn’t leave it for a long time.